Piping maintenance and repairs can result in lengthy production delays, safety risks, and considerable costs for parts and labour. SRJ Technologies is an Asset Integrity Management specialist, backed by a team of globally renowned experts, providing innovative, weld-free solutions to overcome these common issues.

When a major Australian oil refinery experienced a diesel oil leak from an oval bonnet valve, things could have become serious.

Not only was production threatened, but with the hydrocarbon leak at a temperature of 310 degrees Celsius and under pressure, intrusive repairs would be complicated and time-consuming.

Replacing the valve meant waiting for parts to arrive from an overseas supplier - with wait times exacerbated due to COVID-19 restrictions - while the operating environment made patching the leak almost impossible.

But thanks to its local team of specialists and manufacturing capabilities, SRJ Technologies was able to resolve the issue within 48 hours by designing and building a customised solution.

The SRJ team took detailed measurements of the complex geometry, then created a 3D model for a custom enclosure repair to facilitate rapid CNC machining at a local manufacturing facility.

With peripheral seals incorporated into the design, the enclosure fitted to the exact profile of the valve, while a sealing compound was injected through small valves installed into pre-drilled ports. Finger clamps were used to secure the enclosure in place.

The result was a fast, highly effective and long-lasting repair that led to minimal downtime, mitigated risk and allowed the client to continue production almost unhindered.

The SRJ Technologies story

Founded in the UK and recently establishing its Australian headquarters in Perth ahead of an ASX listing planned for later this year, SRJ Technologies is an expert in Asset Integrity Management.

According to CEO Alexander Wood, the company's globally renowned subject matter experts are leaders in integrity management consulting, offering unrivalled expertise to clients in a personalised and highly targeted way.

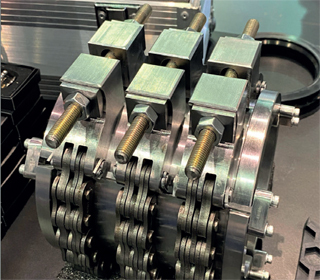

Multi-Shell Repair Clamp

"That approach has culminated in the development of a range of innovative technologies to overcome challenges that were common across multiple sites and assets," Mr Wood said.

"One of the key issues was the need for specialised welding for repairs and maintenance, and with that came production shutdowns that proved exceptionally costly."

To solve these issues, SRJ Technologies now delivers a range of weld-free, precision pipe repair and replacement solutions, as well as services including:

- Leak mitigation and containment management solutions

- Customised repair solutions for piping, flanges and valves

- Bespoke engineering solutions for non-standard requirements

- Specialised repair tools addressing Corrosion Under Insulation (CUI) and Corrosion Under Pipe Supports (CUPS)

- Expert advisory services including risk-driven integrity assessments and optimal repair strategies

Initially targeting the oil and gas industry, the company's specialists identified a range of shortcomings with traditional pipe repair and replacement options.

These included the need to shut down assets to repair or replace defective equipment, the need for specialist pipe welding and its inherent safety risks associated with hot work in hazardous environments, and the considerable time required to source parts and complete repair and maintenance works.

That has led to the design and commercialisation of a range of weld-free pipe couplings, repair clamps and flange reinforcement clamps enabling faster and safer repair turnaround.

SRJ BoltEx Flange Clamp

In addition, due to extensive variations in piping infrastructure, SRJ Technologies has developed repeatable design and manufacturing processes enabling cost-effective, customised solutions.

"By building teams of subject matter experts and licensing our processes to precision manufacturers in key markets around the world, today SRJ Technologies is able to design and deliver solutions with speed and accuracy unheralded across many industry sectors," Mr Wood said.

"We've also introduced new developments focused on digitisation by incorporating sensors into SRJ products that enable real-time data to be captured from operating assets.

"In addition, we recently completed testing to prove our couplings can withstand subsea pressure to depths of 2,000m while transmitting live data such as internal pipeline pressure and temperature."

Mr Wood said SRJ Technologies has expanded its reach to provide solutions that cater for assets across a broad range of industry sectors. These include:

- Oil and Gas (onshore, offshore and midstream assets)

- LNG facilities

- Mining

- Power and other utilities

- Petrochemical plants

- Shipping

"Our objective is to deliver improved repair and maintenance efficiency, maximising the operational life of assets while not compromising on safety," he said.

Leak mitigation and containment management solutions

Multi-Shell Repair Clamp (MSRC)

Designed for both emergency repair and proactive installation to prevent potential loss of containment, the MSRC can be fitted in under 10 minutes without the need for specialised tools.

Ranging from 3" to 12" outside pipe diameter and capable of sealing leaks at pressures up to 50 barg, the MSRC operates effectively at temperatures between -20C and 205C. It includes an innovative, replaceable seal, designed in a hex pattern for enhanced performance. This means the MSRC can be removed and re-used with a quick seal replacement. The multi-shell design ensures optimal clamping arrangement and also allows for use on piping with ovality.

SRJ Weld-Free Pipe Coupling

Designed in accordance with ASME B31.3, SRJ Technologies' Pipe Coupling is Type Approved by Lloyd's Register and ABS for 1.25" to 16" pipe (outside diameter). This includes approvals for hydrocarbon service and as a permanent repair/connection.

Weighing up to 60 per cent less than equivalent flanges, the innovative coupling eliminates the need for hot work and can be installed by a two-person team, thus reducing risk and removing the need for some permitting.

The Weld-Free Pipe Coupling is easy to remove and reinstall, can be utilised in hard-to-access areas such as pipe racks, and includes multiple configurations to address different piping system needs such as pipe to pipe, pipe to flange, blind end, reducer options and more. The fittings also allow rapid spool replacement up to 90 per cent faster than a flanged connection.

Suitable for both brownfield repairs and maintenance, as well as greenfield applications including spool or modular tie-in, the couplings are especially useful where pressure testing is not practical - for example with golden welds.

BoltEx Flange Clamp

SRJ Technologies' BoltEx Flange Clamp is designed to ASME PCC-2, ASME VIII and ASME B16.5 requirements. BoltEx is an innovative repair fitting enabling safe bolt replacement during normal operations. It has been validated by FEA and testing to perform at 1.5 times the rated line pressure with all flange bolts removed.

BoltEx can be used for immediate intervention to replace corroded bolts in accordance with ASME PCC-2 (Hot Bolting), as well as for extending flange life by being left installed as a preventative measure on defected flanges with bolts that cannot be retrieved or replaced.

The key benefits include maintaining flange integrity until the next shutdown opportunity, extending asset life, and thus reducing costs.

Bespoke Enclosure Repairs

SRJ Technologies understands the importance of providing bespoke solutions to overcome critical issues and challenges that prove hard to address with existing solutions.

This has led to the development of specialised design and engineering processes using CNC Machining to quickly manufacture bespoke enclosures. The manufacturing processes are licensed to suppliers in local markets, who work in conjunction with SRJ Technologies' local specialists to resolve client issues.

Expert advisory services

SRJ Technologies focuses on improving asset integrity management performance through combining cutting-edge containment technologies with engineering and operational know-how.

It is this know-how that drives the range of expert advisory services offered by SRJ team, including:

- Asset Integrity Governance

- Management System Consulting

- Design Integrity

- Integrity Problem Solving and Engineering

- Integrity Management of Mature Assets

- Integrity Assessment and Assurance

SRJ Technologies' containment management solutions are the result of consulting services provided to operators around the world. Expert advisory remains at the heart of the company's offerings, with specialist staff taking a partnership approach with clients and EPCM contractors to deliver strategic, risk-driven integrity assessments and define optimal repair strategies.

ABOUT THIS COMPANY

SRJ Technologies

HEAD OFFICE:

- Le Quai House, Le Quai D'Auvergne, St Helier, Jersey JE2 3TN

- Tel: +44 (0) 1534 626 818

- Website: www.srj-technologies.com/

- Email: info@srj-technologies.com